|

|

| Engine features | Engine specifications | Multiple Displacement System |

3.0-L CRD (export) |

3.0-L CRD |

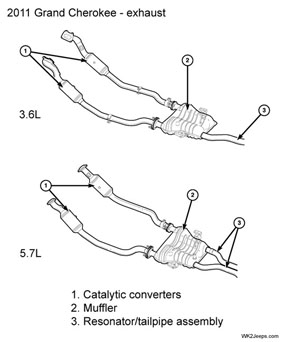

3.6-L V-6 |

|||||

5.7-L V-8 HEMI |

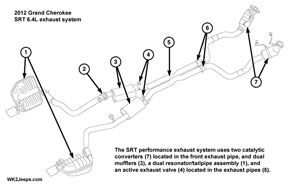

6.4-L V-8 HEMI |

6.2-L V-8 HEMI |

New 3.0-liter turbo, direct-injection V-6 diesel engine now available for the all-new 2011 Jeep® Grand Cherokee. The new engine is more powerful, more fuel efficient and produces lower emissions than its predecessor. Built by VM Motori and developed together with Fiat Powertrain, company of Fiat S.p.a., the new 3.0-liter turbo diesel engine produces maximum power of 177 kW (241 hp DIN) at 4,000 rpm and torque of 550 Nom (406 lb-ft) at 1,800-2,800 rpm. This translates to 10 percent more power and eight percent more torque than the engine it replaces. Even with its improved performance, fuel economy for the new 3.0-liter turbo diesel engine is 8.3 L/100km on the combined cycle, an improvement of 19 percent over the prior diesel engine. CO2 emissions (combined cycle) are also reduced by 20 percent, now at 218 g/km. The new V6 turbodiesel is fitted with new-generation, 1800 bar injectors with new MultiJet II technology, developed and patented by Fiat Powertrain and which made its début in 2009 on the 1.3 Small Diesel Engine equipped on the Punto Evo. Engine Block Structure The new 3.0-liter turbo diesel engine features a compressed graphite iron, 60-degree block with aluminum cylinder heads and a two-piece structural aluminum oil pan. Bore is 83 mm (3.27 in) and stroke is 92 mm (3.62 in) for a total displacement of 2987 cm3 (182 in3). Bore spacing is 96 mm (3.78 in). The engine is compact and lightweight, with overall dimensions of 695 mm (27.36 in) in length, 729 mm (28.7 in) in width and 697.5 mm (27.46 in) in height. Weight of the fully dressed new engine is 230 kg (507 lbs). The engine block features a crankcase architecture with stiffened construction, including a bedplate that provides a rigid and stiff carrier for the crankshaft. This in turn helps reduce overall noise from the lower reciprocating assembly and contributes to significant improvements in overall noise, vibration and harshness. Adding to the structural rigidity of the block, the two-piece aluminum oil pan has been designed to provide strength and contribute to the quietness of the engine. The lower pan has been reinforced for off-road use. Crankcase capacity is 7.7 L (2 gal). Cylinder heads are constructed of aluminum and feature a chain-driven, dual overhead-camshaft design with four valves per cylinder. Intake valves measure 28 mm (1.1 in), and exhaust valves are 24.5 mm (0.96 in) in diameter. Combustion-chamber volume is 24.68 cm3 (1.51 in3). A forged-steel crankshaft is supported by four main bearing journals fitted with four-bolt main bearing caps incorporated into the bedplate. Externally balanced, the crankshaft measures 442.2 mm (17.41 in), reducing the overall packaging requirements of the engine. Connecting rods, with an overall length of 162.9 mm (6.41 in), are constructed of cast iron. Lightweight, cast-aluminum pistons are redesigned to provide minimal friction. The compression ratio of the new diesel engine is now 16.5:1, reduced from 18.1:1 on the previous model, contributing to cleaner combustion and providing more power. All main bearings are a "lead free" design for reduced environmental impact during construction and later recycling of the engine. Engine Performance Features The induction system includes swirl control to optimize combustion. Fitted between the intake system and the combustion chamber, the swirl control effectively provides an ideal air/fuel mixture at all levels of engine speed. Precise fuel delivery is through a 1,800-bar common-rail fuel-injection system. Thanks to the new MultiJet II technology, which makes use of a special balanced solenoid valve, the new injector is capable of making up to 8 injection per cycle with the possibility of managing the two main injections in a single modular profile (IRS - Injection Rate Shaping) thus guaranteeing a reduction in consumption and polluting emissions of approximately 2% compared to a traditional injector and ensuring a drastic reduction in noise levels. The new 3.0-liter diesel engine utilizes a single Garrett VGT 2056 turbocharger with variable turbine geometry. Compact and lightweight, the turbocharger provides near-instant response and includes an air-to-air intercooler. Fuel Economy and Emissions Fuel economy for the Jeep Grand Cherokee with the 3.0-liter turbo diesel engine is rated at 10.3 L/100 km on the urban cycle and 7.2 L/100 km on the extra-urban cycle. For the combined cycle, the fuel economy is rated at 8.3 L/100 km. The engine is designed to run on EN590 ultra-low-sulfur diesel fuel. For this engine, cast-iron exhaust manifolds are utilized. Additional emissions controls include a close-coupled diesel oxidation catalyst and standard diesel particulate filter. Euro 5 emissions are met through an exhaust-gas recirculation (EGR) system that includes an EGR valve with DC motor and a high-performance EGR cooler with bypass valve. CO2 emissions are reduced to 270 g/km for the urban cycle and 188 g/km for the extra-urban cycle. Combined-cycle CO2 emissions are now 218 g/km.

Among all of the many new 2014 Jeep® Grand Cherokee features, two in particular contribute to vastly improved fuel economy and driving performance: a new, clean, 3.0-liter EcoDiesel V-6 engine and a new eight-speed automatic transmission. The result: Jeep has taken the most awarded SUV in history and raised the benchmark even further, achieving fuel economy up to 30 miles per gallon (mpg) in EcoDiesel form, and improved fuel economy, drivability and overall performance across the Grand Cherokee lineup.

Producing a class-leading 240 horsepower and massive 420 lb.-ft. of torque, the 3.0-liter EcoDiesel is capable of towing 7,400 pounds - more than any competitor's V-8 equipped SUVs. With a 30-percent increase in fuel economy and a 56-percent increase in torque versus the Pentastar V-6 engine, the EcoDiesel achieves 21 mpg in the city and 30 mpg on the highway in 4x2 models. This allows for a best-in-class driving range of more 730 miles. Full-time 4x4 models have fuel economy figures of 20 city and 28 highway. The new, 50-state legal, clean 3.0-liter EcoDiesel engine produces low CO2 emissions. MultiJet II common-rail injection and Selective Catalyst Reduction (SCR) help this new engine achieve these results. The 24-valve, dual-overhead-cam engine features a block and bed plate crafted from strong compacted graphite iron (CGI), which contributes to stiffness without penalizing performance. The clean 3.0-liter EcoDiesel's 60-degree cylinder banks enable more efficient packaging, while effectively balancing the potent inertia generated by torque-rich diesels. Driver and passengers alike can expect a smooth, quiet ride on any journey. The new engine's 1-4-2-5- 3-6 firing order helps manage rotation so neatly it needs no balance shaft to deliver the level of refinement for which the Grand Cherokee is known. Further contributing to quieter performance, as well as optimal fuel economy and emissions reduction, is the clean diesel's common-rail fuel-injection system. Its 29,000-psi (2,000-bar) pressure is unmatched by any solenoid-based system. Swirl-control intake ports benefit from a variable-geometry turbocharger and intercooler that ensure the required engine response, whether merging on-road or surging off-road. Temperature extremes are also addressed. The new engine's turbo is water-cooled to handle searing heat, while low-voltage ceramic glow plugs accommodate quicker cold-weather starts. Other key features and benefits include:

The 3.6-liter V-6 engine, part of Chrysler-s $3.6 billion powertrain offensive, is introduced for the first time in the all-new 2011 Jeep Grand Cherokee. The more fuel efficient V-6 engine features 11 percent improved fuel economy, 33 percent improved horsepower, 11 percent improved torque. Environmental-friendly design: lead-free engine, recyclable oil filter element with no-spill removable feature. "The engine team went out and benchmarked the best in V6s - your Toyotas and Hondas. Found all the elements from each of them to come up with the best V6," said Matt Nyquist, Jeep Product Planning. "The all-new Pentastar is the most advanced six-cylinder engine Chrysler has ever offered," said Bob Lee, Vice President - Powertrain Product Team. "This new family of engines uses an architecture conceived with future technology growth and integration in mind." The all-new 3.6-liter V-6 engine is an all-new design featuring double-overhead camshafts (DOHC) and a high-pressure die-cast aluminum cylinder block in a 60-degree configuration. "Our all-new engine delivers better performance and the capability Jeep customers demand." Similar to what we did with the HEMI® engine, our engineers used the best combination of design features and technologies to create an engine that satisfies customer requirements". "The elegantly simple design maximizes the functionality of each design element rather than adding technology to claim a feature. The result gives our customers everything they demand from an engine today - class-leading levels of refinement, fuel-efficiency, performance and cost of ownership." The 3.6-liter V-6 engine design features a double-overhead cam (DOHC) and high-flow intake and exhaust ports, which in combination with VVT via dual independent cam phasing, allows optimum volumetric and combustion efficiency over the full speed and load range. This results in an exceptional, flat torque curve along with high specific power. The engine's torque exceeds 90 percent of its peak value from 1,600 to 6,400 rpm, which provides customers with outstanding drivability and responsiveness. The all-new 3.6-liter V-6 engine will deliver 290 horsepower (216 kW) at 6,350 rpm and 260 lb.-ft. (353 N-m) of torque at 4,300 rpm, an increase of 38 percent in horsepower and 11 percent in torque over its predecessor, while providing customers up to an 11 percent improvement in fuel economy. The Pentastar V-6 is designed to run on regular gasoline, offering a 10 percent reduction in fuel cost compared with premium fueled engines. The engine also is flex-fuel capable, offering consumers the choice of gasoline or E85 fuel. An environmental-friendly oil filter system with optional integrated oil cooler is used to help protect the environment via incineration of the filter element. The use of long-life spark plugs and a high-energy coil-on-plug ignition system also helps reduce cost of ownership. Refinement was a key objective for every component during the design phase of the engine and was achieved by utilizing advanced computer-aided engineering techniques. Structural, intake and exhaust areas of the engine are designed to deliver low levels of overall noise and achieve specific sound quality goals that meet discerning customer requirements. The result is a refined engine in all applications. Idle quality refinement is improved due to use of the dual independent cam phasing. In developing the Jeep Grand Cherokee's all-new 3.6L V6 engine, reliability and quality are assured via extensive validation testing. More than 3.3 million customer equivalent miles were accrued on engine dynamometers prior to production. Test severity was increased by 50% versus previous Chrysler V6 engines in order to accommodate high load applications such as trailer-towing.

The updated 3.6-liter V-6 engine debuting in the 2016 Grand Cherokee adds Engine Stop-Start (ESS) to improve fuel economy and efficiency. The updated engine receives a bump in horsepower, increasing output to 295 horsepower. New Pentastar technology for 2016 also includes cooled Exhaust-Gas Recirculation (EGR), advanced two-step Variable Valve Lift (VVL) system and an upgraded variable-valve timing (VVT) system that reduces pumping losses and improves combustion. ESS technology increases fuel efficiency by shutting the engine off when the vehicle comes to a complete stop. Amenities (radio, gauges, heating or air conditioning, etc.) continue to operate, making the operation transparent to the driver. The engine restarts automatically when the driver releases the brake, allowing seamless acceleration. ESS is activated automatically and requires no input from the driver. A system disable switch is located on the dash if the operator wishes to suspend the feature.

The HEMI's new VVT improves fuel economy under some conditions in two ways. First, it reduces the engine's pumping work by closing the intake valve later. Second, it increases the expansion process of the combustion event. This allows more work to be transferred to the crankshaft instead of being rejected out of the exhaust port as heat. Essentially, VVT optimizes engine breathing, which improves engine efficiency and power. The fuel-saving MDS system seamlessly alternates between smooth, high- fuel-economy four-cylinder mode when less power is needed, and V-8 mode when more power from the new 5.7-liter HEMI engine is in demand. An expanded MDS operating range in the new-for-2009 HEMI will allow customers to realize an even-greater fuel economy benefit. When MDS is operating, it is indicated by the fuel-economy- mode readout in the Electronic Vehicle Information Center. For the 2011 model year, the 5.7L produces increased power and torque over the previous model, delivering 360 horsepower (268 kW) and 390 lb.-ft. of torque (520 N-m) @ 4,250 rpm and features Variable-valve Timing (VVT) and fuel-saving MDS technology with dual exhaust to maximize efficiency - 14 city / 20 hwy-2WD and 13 city / 19 hwy-4WD (estimated EPA Fuel Economy mpg).

The 6.4L HEMI eight-cylinder SRT high performance engine is a 90° V-Type, deep skirt, lightweight cast iron block with aluminum heads, single cam, overhead valves, and hydraulic roller lifters. The heads incorporate splayed valves with a hemispherical style combustion chamber and dual spark plugs. The cylinders are numbered from front to rear; 1, 3, 5, 7 on the left bank and 2, 4, 6, 8 on the right bank. The firing order is 1-8-4-3-6-5-7-2. The 6.4L HEMI engine is a bored and stroked version of the 5.7L HEMI engine developed for SRT high performance vehicles. This engine shares the same architecture as the 2009 5.7L HEMI with the following Performance Upgrades:

Powering the 2012-up Jeep Grand Cherokee SRT8 is Chrysler Group's all-new 6.4-liter HEMI V-8 with Fuel Saver Technology that delivers 470 horsepower and 465 lb.-ft. of torque - an improvement of 50 horsepower and 45 lb.-ft. torque over the 6.1-liter HEMI V-8 it replaces. The newest HEMI engine in the SRT product lineup provides an additional 90 lb.-ft. of torque at 2,900 rpm versus the previous 6.1-liter V-8 engine. An active intake manifold and high-lift camshaft with cam phasing delivers maximum low-end torque while optimizing high-end power across a wider and improved rpm band. Specifically, 90-percent of peak torque is available between 2,800 and 6,000 rpm, allowing for inspired standing starts and improved straight-line performance. Standard Fuel Saver Technology and a new-for-2012 active valve exhaust system allows four-cylinder operation to engage over a wider rpm range, to deliver both improved fuel efficiency - an estimated 13-percent increase on the highway - and an extended range of approximately 450 miles on one tank of gas. Of course, even SRT owners sometimes appreciate driving more fuel efficiently. For those times, the 2014 Grand Cherokee SRT features an innovative Eco Mode that optimizes the transmission's shift schedule and expands the range of Fuel Saver Technology, which - when conditions are right - deactivates four cylinders to conserve fuel. Eco Mode is available in Selec-Track auto mode. Throttle mapping, transmission shift schedules and Fuel Saving Technology work in combination to achieve maximum fuel efficiency.

Powering the 2018 Jeep Grand Cherokee Trackhawk is a supercharged 6.2-liter V-8 engine delivering 707 horsepower and 645 lb.-ft. of torque. The breakthrough supercharged engine is designed and manufactured using only the strongest and most durable materials. Its cast iron block features water jackets between the cylinders for optimal cooling. A forged-steel crankshaft with induction-hardened bearing surfaces is so strong it can withstand firing pressures of nearly 1,600 psi (110 bar) - the equivalent of five family sedans standing on each piston, every two revolutions. The unique, specially tuned crankshaft damper has been burst tested to 13,000 rpm. High-strength, forged-alloy pistons - developed using advanced telemetry measurement - are coupled to powder-forged connecting rods with high-load-capacity bushings and diamond-like, carbon-coated piston pins. Premium grade, heat-treated aluminum-alloy cylinder heads are optimized for superior thermal conductivity. Sodium-cooled exhaust valves feature hollow-stem construction and special steel-alloy heads that stand up to temperatures as high as 1,652 degrees Fahrenheit (900 degrees Celsius). The 2,380cc per revolution supercharger includes integral charge-air coolers and an integrated electronic bypass valve to regulate boost pressure to a maximum of 11.6 psi (80 kPa). The twin-screw rotors are specially coated with:

The coating enables tighter clearance between the rotors. This reduces internal air leakage, delivering improved compressor performance and higher efficiencies. The coating can withstand the temperatures generated by compression, and provides superior corrosion resistance. The supercharger is sealed for life with premium synthetic oil, uses a drive ratio of 2.36:1 and has a maximum speed of 14,600 rpm. The supercharger drive system's one-way clutch de-coupler improves refinement, while allowing for precisely the kind of powerful sound certain to captivate Jeep Grand Cherokee Trackhawk drivers. Air sources for the supercharger include a cold-air scoop in the lower front fascia, which replaces the driver's-side fog lamp and helps to feed the 92mm throttle body. The large-nosed crankshaft drives a high-flow gerotor oil pump, which feeds a lubrication circuit that includes eight high-flow piston-cooling jets. A high-capacity oil/air heat exchanger, mounted in the front of the Trackhawk, mitigates oil temperatures when driving conditions are harshest, such as on the track. A new low-temperature cooling system, consisting of a pump, reservoir, heat exchanger and lines, help keep the charge air cool during performance driving. This system is designed to keep intake air temperatures below 140 degrees Fahrenheit (60 degrees Celsius), under extreme ambient conditions, while enabling air flow of up to 30,000 liters per minute. A new fuel delivery system, featuring two high-flow, multi-mode pumps, matches the high-performance demands of the engine.

--WK2Jeeps.com

|

|

||||||||||||

| Description | 3.0-L CRD (export only) | 3.6-L V6 | 5.7-L V8 HEMI | 6.4-L V8 HEMI | 6.2-L V8 HEMI | |||||||

| General | ||||||||||||

| Air cleaner element / Intake system | Dry Filter with Turbocharger and Charge Air Cooler | Low restriction air intake system | Low restriction air intake system | Low restriction air intake system | Low restriction air intake system | |||||||

| Bore x stroke | 83.0mm (3.26 in.) 92.0mm (3.62 in.) |

96.0mm (3.78 in.) 83.0mm (3.27 in.) |

99.5mm (3.92 in.) 90.9mm (3.58 in.) |

103.9 mm (4.09 in.) 94.6 mm (3.72 in.) |

103.9 mm (4.09 in.) 90.9 mm (3.58 in.) |

|||||||

| Coolant capacity | 4.9 qt. (4.6-liters) | 14.0 qt. (13.25-liters) | 14.5 qt. (13.72-liters) | 14.0 qt. (13.25-liters) | 14.7 qt. (13.90-liters) | |||||||

| Compression Ratio | 16.5:1 | 10.2:1 | 10.5:1 | 10.9:1 | 09.5:1 | |||||||

| Displacement | 3.0 Liters / 182 C.I. | 3.6 Liters / 220 C.I. | 5.7 Liters / 345 C.I. | 6.4 Liters / 392 C.I. | 6.2 Liters / 370 C.I. | |||||||

| Engine type | CRD | 60° V-6 | 90° V-8 HEMI | 90° V-8 HEMI | 90° V-8 HEMI | |||||||

| Engine speed, maximum | 4200 RPM (4800 in Neutral) | 7200 RPM | 5800 RPM | 6400 RPM | 6200 RPM | |||||||

| Exhaust manifold | The exhaust manifolds are tube in shell air gap design to maximize durability and performance. The exhaust manifolds are made of stainless steel stamped shells and stainless steel tubes with a powdered metal outlet. A layered graphite over perforated steel manifold gasket is used to provide sealing to the cylinder head. | |||||||||||

| Firing Order | 1-4-2-5-3-6 | 1-4-2-5-3-6 | 1-8-4-3-6-5-7-2 | 1-8-4-3-6-5-7-2 | 1-8-4-3-6-5-7-2 | |||||||

| Fuel requirement | EN590 ultra-low-sulfur diesel fuel | E85 (Ethanol) or unleaded regular, 87 octane

(R + M)/2

Premium is NOT recommended |

Mid-grade 89 octane

Acceptable: Premium is NOT recommended |

Premium 91 octane (R+M)/2 | Premium 91 octane (R+M)/2 | |||||||

| Fuel Economy (City/Hwy) | 10.3 L/100 km on the urban cycle and 7.2 L/100 km on the extra-urban cycle. For the combined cycle, the fuel economy is rated at 8.3 L/100 km. | 16/23 (2WD) 16/22 (4WD) |

14/21 | 13/19 | 11/17 | |||||||

| Injectors | CRI 2-18 | flow = 22.5 lb/hr @ 49psi | ||||||||||

| Intake manifold | The intake manifold is made of a composite material and features a dual shaft Short Runner Valve (SRV) system to maximize both low end torque and peak power. The SRV is bolted to the rear of the intake manifold and can be service separately from the manifold. The manifold uses a single plane sealing system with individual port seals and a separate PCV port seal to prevent leaks. | |||||||||||

| Knock sensor(s) | Two (Stereo) | Two (Stereo) | Two (Stereo) | |||||||||

| Lead Cylinder | # 1 Left Bank | # 1 Left Bank | # 1 Left Bank | # 1 Left Bank | # 1 Left Bank | |||||||

| Oil Capacity | 9.7 quarts | 6 Quarts | 7 Quarts

(Note: 5W-20 oil MUST be used for proper operation of 5.7L MDS system) |

7 Quarts (5W-40 Synthetic) |

8.3 Quarts (5W-40 Synthetic) |

|||||||

| Oil cooler, engine | The engine oil cooler is engineered for maximum cooling efficiency with no restriction in oil flow. The oil cooler is a stack plate design coolant-to-oil heat exchanger. The oil cooler is mounted between the oil filter and the engine block. The oil cooler uses the radiator coolant system; coolant is circulated through two coolant hoses to maintain a consistent engine oil temperature. | |||||||||||

| Oil cooler, piston | Four dual-nozzle oil jets are bolted to the cylinder block underneath the main oil gallery. The jets connect with an oil-tight fit to the main gallery through lubrication passages. Each oil jet helps cool the two opposing pistons. | |||||||||||

| Oil pressure | At curb idle: 10 psi minimum @3800 rpm: 36 psi |

At curb idle: 04 psi minimum @3200 rpm: 25-110 psi |

At curb idle: 04 psi minimum @3000 rpm: 25-110 psi |

At curb idle: 04 psi minimum @3000 rpm: 25-110 psi |

||||||||

| Power (SAE net) | 241 BHP @ 4000 RPM | 290 BHP @ 6350 RPM | 360 BHP @ 5150 RPM | 465 BHP @ 6000 RPM | 707 BHP @ 6000 RPM | |||||||

| Spark plugs |

P/N SP149125AD (Champion)

Type: RER8ZWYCB4 0.40 in. gap |

P/N SLZFR5C11 (NGK) Type: ZFR5C11 0.40 in. gap (*NOTE: The 5.7L V-8 is equipped with torque critical tapered design spark plugs. Do not exceed 15 ft. lbs. torque.) |

||||||||||

| Torque (SAE net) | 406 LB-FT @ 1800-2800 RPM | 260 LB-FT @ 4300 RPM | 390 LB-FT @ 4250 RPM | 465 LB-FT @ 4200 RPM | 645 LB-FT @ 4800 RPM | |||||||

| Valve system | 24 valves and hydraulic end-pivot roller rockers. | Pushrod-operated overhead valves, 16 valves, eight deactivating and eight conventional hydraulic lifters, all with roller followers. | Pushrod-operated overhead valves, 16 valves with sodium-filled exhaust valves

and hollow stem intake valves, 16 conventional hydraulic lifters, all with roller tips

Both the intake and exhaust valves are made of steel with full chrome plate on valve stems. The intake valve is 54.3 mm (2.14 in.) diameter and the exhaust valve is 42.0 mm (1.65 in.) diameter. All valves use three bead lock keepers and retainers to retain the springs and promote valve rotation. The valve guides are made of powdered metal and are pressed into the cylinder head. The guides are not replaceable or serviceable, and valve guide reaming is not recommended. If the guides are worn beyond acceptable limits, replace the cylinder heads. |

|||||||||

| Valve lift (zero lash) | Intake 12.00 mm (0.472 in.) Exhaust 11.70 mm (0.460 in.) |

Intake 14.65 mm (0.577 in.) Exhaust 13.65 mm (0.537 in.) |

||||||||||

| Valve springs (intake and exhaust unless noted) |

7.4 coils 5.39 × 4.52 mm wire diameter |

8.55 coils 5.65 × 4.51 mm wire diameter |

||||||||||

| Weight, engine | 507 lbs. (230 kg) | |||||||||||

| Cylinder Block etc. | ||||||||||||

| Camshaft | Chain Driven Dual Overhead Camshafts | Chain Driven Dual Overhead

Camshafts

The 3.6L engine is equipped with Variable Valve Timing (VVT). This system adjusts the timing of all four camshafts independently using solenoids and oil control valves to direct oil pressure into the camshaft phaser assemblies. The camshaft phaser assembly advances and/or retards camshaft timing to improve engine performance, mid-range torque, idle quality, fuel economy, and reduce emissions. The four VVT solenoids are located on the front of the cylinder head covers. |

Hollow Assembled End play.080 - 0.290mm (0.0031 - 0.0114 in.) |

Cast iron

The 6.4L engine is equipped with Variable Valve Timing (VVT). This system uses an Oil Control Valve (OCV) to direct oil pressure to the camshaft phaser assembly. The camshaft phaser assembly advances and/or retards camshaft timing to improve engine performance, mid-range torque, idle quality, fuel economy and reduce emissions. The OCV is located under the intake manifold. The Variable Valve Timing (VVT) assembly is actuated with engine oil pressure. The oil flow to the VVT assemblies are controlled by an Oil Control Valve (OCV). The OCV consist of a Pulse Width Modulated (PWM) solenoid and a spool valve. The PCM actuates the OCV to control oil flow through the spool valve into the VVT assemblies. The VVT assembly consists of a rotor, stator, and sprocket (Phaser). The stator is connected to the timing chain through the sprocket. The rotor is connected to the camshaft. Oil flow in to the VVT assembly rotates the rotor with respect to the stator, thus rotating the exhaust camshaft with respect to the timing chain and intake camshaft. An infinitely variable valve timing position can be achieved within the limits of the hardware. The CMP monitors the position of the camshaft with respect to the crankshaft and provides feedback to the PCM. |

||||||||

| Crankshaft | Forged-steel, supported by four main bearing journals fitted with four-bolt main bearing caps incorporated into the bedplate, externally balanced |

Nodular iron Out of round0.005 mm (0.0002 in.) End play Bearing Clearance Taper (max.) |

Forged Steel | |||||||||

| Cylinder Block | Compressed graphite iron, 60-degree block with aluminum cylinder heads | Deep-skirt cast-iron block with cross-bolted main bearing caps Aluminum alloy heads with hemispherical combustion chambers |

Cast iron | |||||||||

| Main bearings | Journal diameter 72.0 mm (2.8346 in.) |

Journal diameter 64.988 - 65.012 mm (2.5585 - 2.5595 in.) |

Journal diameter 43.633 - 58.2 mm (1.72 - 2.29 in.) |

|||||||||

| Pistons | ||||||||||||

| Diameter | 82.833 mm (3.2611 in.) |

95.995 mm ± 0.005 mm (3.7793 in. ± 0.0002 in.) |

||||||||||

| Material | Cast aluminum alloy | Aluminum alloy | ||||||||||

| Weight | 354-364 grams (12.487 - 12.840 oz.) | 413 grams (14.56 oz.) | 435 grams (15.34 oz.) | |||||||||

| Piston Pins | ||||||||||||

| Clearance in Piston | 0.030 - 0.050 mm (0.0012 - 0.0020 in.) |

0.005 - 0.014 mm (0.00001 - 0.0005 in.) |

0.0245 - 0.0515 mm (0.00096 - 0.0020 in.) |

|||||||||

| Diameter | 21.9985 ± 0.0015 mm (0.86608 ± 0.00006 in.) |

24.004 - 24.007 mm (0.945 - 0.9451 in.) |

||||||||||

| Valve Timing | ||||||||||||

| Intake - Opens (BTDC) | 5° | 36° | ||||||||||

| Intake - Closes (ATDC) | 255.0° | 250.0° | ||||||||||

| Intake - Duration | 286.0° | |||||||||||

| Exhaust - Opens (BTDC) | 236.0° | 278.0° | ||||||||||

| Exhaust - Closes (ATDC) | 32.0° | 10.0° | ||||||||||

| Exhaust - Duration | 269.3° | 288.0° | ||||||||||

| Valve Overlap | 37.0° | 46.0° | ||||||||||

|

|

|

WKJeeps.com website Premier Sponsor Discount Jeep Parts and Accessories |